How to Choose Private Label Coffee Capsules for your Business

Updated Feb. 11, 2026

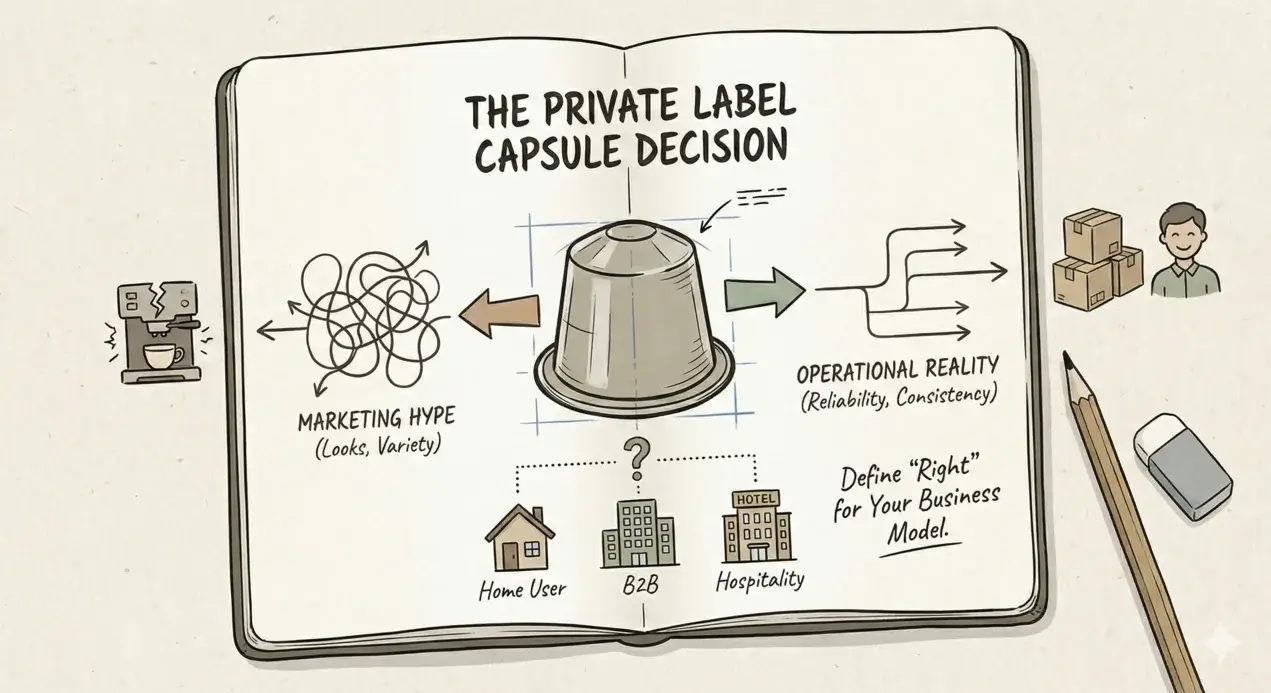

Choosing private label coffee capsules is often treated as a branding or packaging decision. In reality, it is one of the most consequential operational choices a coffee business can make. The capsule you choose determines far more than how your product looks on a shelf. It affects extraction quality, machine compatibility, customer complaints, repeat orders, logistics costs, and ultimately how reliable your brand feels in everyday use. A beautifully branded capsule that leaks, jams machines, or delivers inconsistent cups can quietly erode trust, long before marketing has a chance to work.

So how do you approach capsule selection as a structured business decision rather than a leap of faith? Let’s walk through the real questions private label coffee brands need to answer. Whether you are launching your first private label capsule line or refining an existing one, read on to understand how to choose capsules that perform consistently, scale reliably, and support your brand long after the initial launch:

What does “the right private label capsule” mean for your business model?

Before comparing capsule formats, materials, or suppliers, it is essential to define what “right” actually means for your business. There is no universally best private label coffee capsule. The optimal choice depends on how you sell, who you sell to, and what kind of experience you are trying to deliver consistently at scale.

For a direct-to-consumer brand, the priority may be taste differentiation, visual appeal, and compatibility with the most common home machines. For B2B channels such as offices, hotels, co-working spaces, or events, the definition of “right” often shifts toward reliability, speed, and minimal operational friction. In these environments, a capsule that works every time and produces a predictable cup is usually more valuable than a wider or more experimental range.

It is also important to be explicit about your primary success metric. Some brands optimize for lowest cost per cup, others for premium perception, and still others for operational simplicity or sustainability positioning. Each of these priorities pushes capsule selection in a different direction. Clarifying this early helps avoid mismatches later, such as choosing a capsule that supports a premium message but struggles with defect rates at volume.

A practical way to anchor decisions is to treat capsule choice as a constraint-setting exercise. Once you define your target customer, sales channel, and non-negotiables, such as machine compatibility or defect tolerance, many options will naturally fall away. What remains is not the “best” capsule in abstract terms, but the capsule that fits your business model and allows you to scale with fewer surprises.

Who is your real end user and what machine are they using?

One of the most common mistakes in private label capsule projects is designing for an imagined customer instead of the real end user. In capsule coffee, the machine matters as much as the coffee itself. Your product is only as good as how it performs in the machines already sitting on countertops, office kitchens, hotel pantries, or event spaces.

For consumer-focused brands, this usually means understanding which capsule systems dominate your target market and which specific machine generations are still in active use.

In B2B environments, the gap between expectation and reality can be even wider. Offices and co-working spaces often rely on heavily used machines that prioritize speed and reliability over finesse. Hotels may standardize on a limited set of machines to simplify housekeeping and maintenance. Events often use portable setups where consistency and ease of use matter more than nuanced flavor differences. Each of these contexts places different demands on the capsule, even if the coffee inside is identical.

Understanding your real end user also means separating your personal preferences from operational facts. You might love a specific system at home, but if your customers overwhelmingly use another one, your capsule choice should follow them. The most successful private label capsule programs start by mapping the installed machine base of their audience and treating that map as a fixed reality. Only then do they begin to make decisions about formats, materials, and suppliers.

Which capsule ecosystems are open enough for private label brands to compete in?

Not all capsule systems are equally accessible to private label brands, even if they appear similar on the surface. From a business perspective, one of the most important distinctions is whether a system is truly open to third-party capsules or structurally designed to limit them. This difference affects your freedom to source capsules, control costs, and scale without unexpected constraints.

Some ecosystems, such as Nespresso, are mechanically straightforward and widely adopted, which makes them attractive for private label programs. In these systems, compatibility is primarily a matter of precise dimensions, sealing performance, and material behavior under pressure. If those parameters are respected, third-party capsules can perform reliably across a wide range of machines.

Other systems introduce additional layers of control. While these formats may offer certain user experience advantages, they often reduce flexibility for private label brands. Access can be limited, development costs higher, and long-term dependence on specific partners more likely. For a young or growing brand, this can translate into slower time to market and higher strategic risk.

When evaluating ecosystems, it is useful to look beyond current compatibility claims and ask how the system evolves over time. An ecosystem that is open today but frequently changes specifications can create ongoing validation work and instability. For most private label businesses, especially at launch, choosing an ecosystem with a stable, well-understood compatibility landscape reduces risk and allows you to concentrate on building demand rather than troubleshooting platform barriers.

Should you start with pre-filled capsules or empty capsules you fill yourself?

One of the earliest strategic decisions in a private label capsule project is whether to launch with pre-filled capsules or to purchase empty capsules and handle filling locally. Both approaches can work, but they imply very different operational responsibilities, risk profiles, and levels of control.

Pre-filled capsules are often the fastest route to market. They reduce complexity by consolidating capsule production, filling, sealing, and quality control into a single supply chain. For brands that want to validate demand quickly, minimize operational overhead, or focus primarily on sales and marketing, this option can be attractive. The trade-off is reduced flexibility. You are more dependent on your supplier’s coffee sourcing, roast profiles, capsule quality and production schedules, and changes typically take longer to implement.

Empty capsules paired with local filling give brands far more control over the coffee itself. This model allows you to align capsule performance with your own roasting style, freshness standards, and regional taste preferences. It can also support international growth by enabling local production closer to end markets, which reduces transport times and simplifies customization. The cost of this control is responsibility. You must manage filling accuracy, sealing quality, hygiene standards, and ongoing process consistency, all of which directly affect capsule performance.

The right choice depends on your capabilities and long-term plans. Brands with strong roasting operations and quality systems often prefer empty capsules because they integrate more naturally into existing workflows. Brands focused on speed, simplicity, or early-stage validation may benefit from starting with pre-filled capsules and reassessing later. What matters most is being honest about what you can control well today, not what you hope to control eventually.

How do you choose the capsule material?

Capsule material is often framed as a branding or sustainability decision, but in practice it is also a performance and risk decision. The material you choose influences how well the capsule protects the coffee, how it behaves under pressure, how consistently it seals, and how tolerant it is of machine variability.

Plastic capsules can be more forgiving from a production standpoint and may offer lower upfront costs. However, their barrier properties are typically weaker, which can affect freshness over time. Performance can also vary more across different machines, particularly older ones. From a perception standpoint, plastic may conflict with premium positioning, depending on the market and audience.

Compostable capsules appeal to sustainability-conscious customers, but they require especially careful validation. Performance can be sensitive to humidity, storage conditions, and machine pressure, and claims around compostability must be accurate and well documented. Not all compostable capsules behave consistently across real-world environments, which makes testing and clear communication essential.

Aluminum capsules are widely used in premium and professional contexts because they offer excellent barrier properties against oxygen, light, and moisture. This helps preserve aroma and flavor over shelf life.

Aluminum is also structurally strong, which supports consistent extraction when tolerances and sealing are properly controlled. The downside is that aluminum capsules demand precise manufacturing and sealing processes. Weak seals or inconsistent rims can lead to leaks or machine issues, especially at scale. NovoCapsule offers Swiss precision manufacturing and high quality recycled aluminum capsules that have a wider seal than the typical capsule on the market, providing you with the peace of mind that comes with knowing your coffee is as protected as possible and stays as fresh as when it first arrived from the grower.

Rather than starting with material ideology, it is often more productive to start with use conditions. Consider shelf life requirements, distribution channels, machine diversity, and the level of process control you can realistically maintain. The best material choice is the one that aligns performance, risk tolerance, and brand positioning in a way you can sustain over time.

What compatibility risks should you worry about before you worry about branding?

In private label capsule projects, most brand damage does not come from weak design or unclear positioning. It comes from compatibility failures that customers experience repeatedly and rarely forgive. Before investing heavily in branding, it is critical to understand the main technical risks that cause capsules to fail in real machines.

The most common issues include leakage during brewing, capsule rupture under pressure, incomplete extraction, and machine jams. These problems are usually not random. They are the result of small deviations in capsule dimensions, material thickness, rim geometry, or sealing quality. Even minor inconsistencies can be amplified when capsules are used across different machine models, especially older or heavily used ones.

Compatibility is not a single yes or no condition. A capsule may technically fit into a machine, yet still perform poorly. For example, weak sealing can lead to slow leaks that dilute the coffee or leave residue inside the machine. Incorrect capsule stiffness can affect how water flows through the coffee bed, producing cups that are thin, bitter, or inconsistent from shot to shot. From the customer’s perspective, these issues feel like product unreliability, not engineering nuance.

The key takeaway is that compatibility risk is a brand risk. Every failure becomes part of your reputation, even if the root cause is invisible to the user. Treating compatibility as a core quality requirement, with defined tolerances, testing protocols, and acceptance criteria, protects your brand far more effectively than any visual or marketing upgrade.

What should you ask a capsule supplier to prove about quality and process control?

Choosing a capsule supplier is not about finding the most reassuring sales pitch. It is about verifying that the supplier can produce the same capsule, to the same precise specifications, every time you reorder. Without evidence of process control, even a strong pilot run can quietly degrade into inconsistent production over time.

Start by asking for measurable specifications, not general assurances. This includes defined dimensional tolerances for critical areas such as the rim, seal, height, and skirt, as well as material thickness and sealing parameters. A serious supplier should be able to explain which dimensions are controlled, how they are measured, and how often those measurements are taken during production.

Process control also means traceability. You should be able to trace capsules back to specific production lots, materials, and dates. Ask how defects are tracked, what acceptable defect thresholds are, and what corrective actions are taken when a batch falls outside agreed limits. If a problem occurs in the market, clear traceability determines whether it becomes a manageable issue or a costly recall.

Finally, ask how change is managed. Suppliers sometimes adjust materials, tooling, or processes to improve efficiency, but even small changes can affect compatibility. A reliable partner will have a formal change control process and will not implement modifications that affect performance without validation and customer approval. These questions may feel technical, but they are ultimately about protecting your brand from instability as volumes grow.

Which certifications are worth caring about in capsule supply chains?

Certifications are often treated as a checkbox exercise, but in private label capsule programs they can signal how disciplined and transparent a supplier’s operations really are. The key is not to collect as many certifications as possible, but to understand which ones are relevant to your role in the supply chain and to the expectations of your customers.

For capsule manufacturing and packaging materials, recognized packaging standards indicate that a supplier follows structured controls around hygiene, material safety, and traceability. This matters even if you are not handling food directly. Capsules are food contact components, and large buyers, retailers, and distributors often expect documentation that shows how packaging risks are managed at scale.

If your supplier is also filling and sealing capsules, food safety management certifications become more relevant. These frameworks typically cover hazard analysis, process monitoring, and corrective actions, all of which directly influence product consistency and safety. Even when certification is not legally required, it often reflects a level of operational maturity that reduces risk for private label brands.

A practical way to evaluate certifications is to work backward from your sales channels. Corporate clients, hotel groups, and retailers may request specific documentation during onboarding. Aligning your supplier’s certifications with those expectations early avoids last-minute gaps that can delay deals or limit growth opportunities.

How do you choose coffee specs that actually work in capsules, not just in cupping?

Coffee that performs beautifully in cupping does not automatically perform well in a capsule system. Capsules impose strict physical limits on extraction, and ignoring those constraints is a common reason private label products fail to meet expectations once they reach customers.

In capsule brewing, grind size, dose, and roast level must work together within a very narrow window. Too fine a grind or too high a dose can increase resistance and lead to under-extraction or machine stress. Too coarse or too light, and the result is a thin, weak cup that feels disappointing, especially to repeat drinkers. Because water flow is largely dictated by the capsule and machine design, you have less room to compensate after the fact.

Freshness management is also different. Capsules require careful control of degassing time and oxygen exposure before sealing. Coffee sealed too early or too late can behave unpredictably during extraction. This makes coordination between roasting, filling, and sealing schedules essential, particularly if you are working with empty capsules and local filling.

The most reliable approach is to design coffee specifically for the capsule format rather than adapting existing blends. This means defining target extraction parameters, testing on real machines with consistent water conditions, and using repeatable sensory evaluation rather than one-off tastings. When coffee specs are built around capsule realities, consistency improves and customer trust follows.

What should your first product line look like: narrow and reliable or broad and exciting?

When launching private label coffee capsules, there is a strong temptation to showcase range. Multiple roast levels, origins, flavored options, and limited editions can feel like a statement of ambition. In practice, especially at the beginning, breadth often increases risk faster than it increases value.

A narrow, well-chosen initial lineup allows you to focus on reliability. Fewer SKUs mean fewer variables to control: fewer coffee specs, fewer packaging configurations, simpler forecasting, and more consistent quality monitoring. This is particularly important in capsule programs, where small deviations can have outsized effects on performance. For many brands, two or three core blends are enough to satisfy the majority of preferences while keeping operations manageable.

From a B2B perspective, simplicity is often a competitive advantage. Offices, hotels, and co-working spaces typically prioritize consistency and ease of ordering over novelty. A concise range that works predictably across machines reduces decision fatigue for buyers and minimizes the risk of stockouts or complaints. Once trust is established, expanding the range becomes easier and safer.

A useful way to think about your first product line is as a proof of reliability rather than a full expression of your brand. Start with capsules that you can produce consistently, supply confidently, and support operationally. Excitement can be layered in later, but reliability is what earns repeat business and long-term contracts.

How do you evaluate MOQs, lead times, and hidden costs in capsule programs?

Minimum order quantities and lead times are often presented as simple commercial terms, but in capsule programs they shape your risk exposure more than many brands expect. Packaging tooling, printed components, and private label setup costs can quickly push MOQs higher than what feels comfortable, especially for a first launch. Understanding what drives those numbers helps you judge whether they are reasonable or a warning sign.

Lead times deserve equal scrutiny. Capsules involve multiple coordinated steps, including material production, filling, sealing, quality checks, and logistics. Long or inflexible lead times reduce your ability to respond to demand changes, correct issues, or adjust formulations. Ask suppliers how lead times change once a program is running, not just for the first order, and what happens if demand spikes or a batch needs to be reworked.

Hidden costs are where many private label capsule projects struggle. These include higher-than-expected defect rates, customer support time spent handling complaints, replacements for damaged machines, expedited shipping to cover delays, and storage costs for slow-moving SKUs. None of these appear in the initial price per capsule, but all of them affect profitability and internal workload.

A practical evaluation goes beyond unit price. Compare suppliers based on total cost of ownership, including reliability, flexibility, and the likelihood of operational friction. A slightly higher capsule cost can be justified if it reduces downstream issues and allows you to scale with fewer interruptions and fewer unpleasant surprises.

How do you build sustainability and compliance into capsule choice without greenwashing?

Sustainability has become a baseline expectation in many markets, but in capsule coffee it is also one of the easiest areas to overpromise and underdeliver. Building a credible sustainability position starts with understanding what you can substantiate today and what regulations and buyer expectations are likely to demand tomorrow.

From a compliance perspective, packaging rules are tightening, particularly in the EU. Coffee capsules and their secondary packaging are increasingly expected to be recyclable, clearly labeled, and supported by documentation that explains material composition and disposal routes. Choosing a capsule format that aligns with these requirements reduces future rework and protects you from having to redesign packaging under regulatory pressure.

From a brand perspective, clarity matters more than ambition. Vague language or generic sustainability claims can quickly undermine trust, especially with B2B buyers who are accountable to their own sustainability policies.

A practical approach is to treat sustainability as a system decision rather than a single feature. Consider capsule material, secondary packaging, labeling, logistics, and customer guidance together. When sustainability choices are grounded in real performance and compliance readiness, they strengthen your brand instead of creating risk.

What tests should you run before you commit to a full production run?

Before moving into full-scale production, testing should shift from product approval to risk elimination. At this stage, the goal is not to confirm that the capsule can work, but to verify that it works reliably under conditions that reflect how customers will actually use it.

Mechanical and brew validation should be carried out across a representative set of machines, not just a single lab unit or a new reference model. This means testing different machine versions, including older and heavily used ones, and observing performance across multiple brew cycles. You are looking for repeatability: stable extraction, no leaks, no capsule deformation, and no machine errors. Testing under varied conditions such as different water hardness levels, temperatures, and usage intensity helps reveal weaknesses that controlled environments often hide.

A disciplined pilot run is the next critical step. This should be produced using the same processes, materials, and settings planned for commercial production. Every pilot batch must be traceable at lot level, with clear documentation of when and how it was produced. Acceptance criteria should be defined in advance, including defect thresholds and performance benchmarks, so results can be evaluated objectively rather than emotionally.

After the pilot, a structured post-pilot review is essential. Assess performance data, defect rates, and customer-like feedback from testing users. Based on this evidence, make a deliberate decision to move forward, pause and correct issues, or stop and rethink the approach entirely. Treating this decision as data-driven rather than aspirational protects your brand from scaling problems that become far more expensive once the product is in the market.

How do you choose capsules differently for B2B customers like offices, hotels, events, and co-working spaces?

B2B environments place very different demands on coffee capsules than consumer settings, even when the machines look similar. In these contexts, coffee is part of an operational flow, not a personal ritual. Capsule choice therefore needs to support speed, reliability, and predictability above all else.

In offices and co-working spaces, machines are used frequently, often by people with little interest in learning how they work. Capsules must load easily, brew consistently, and leave minimal residue. A small, clearly defined assortment is usually preferable to a wide range, because it simplifies ordering, storage, and replenishment. From the buyer’s perspective, fewer complaints and fewer machine issues matter more than offering every possible flavor profile.

Hotels introduce a different set of priorities. Guest rooms and breakfast areas require capsules that work flawlessly on the first attempt, because staff cannot troubleshoot every machine. Failures translate directly into guest dissatisfaction. Here, capsule robustness, seal integrity, and predictable extraction matter more than experimentation. Packaging also plays a role, as capsules must be easy to handle, store, and replenish during housekeeping routines.

Events are the most demanding environment of all. Machines may be moved, water quality may vary, and usage is often intense over short periods. Capsules must perform under pressure, literally and figuratively. Speed of preparation, low failure rates, and minimal cleanup are critical, while subtle flavor differentiation is usually secondary.

Final Thoughts:

Choosing private label coffee capsules is ultimately about reducing uncertainty. Every decision you make, from ecosystem selection to supplier agreements, either removes risk from your operation or quietly adds to it. The brands that succeed over time are rarely the ones that chase the most options or the loudest claims. They are the ones that build systems they can understand, measure, and control.

A thoughtful capsule strategy gives you leverage. It allows you to scale without constant firefighting, to say yes to new customers with confidence, and to make changes deliberately instead of reactively. It also creates a foundation where marketing, sales, and sustainability efforts are supported by products that perform as expected in the real world.

If there is one guiding principle to take forward, it is this: treat capsule selection as a long-term operating decision, not a one-off launch task. When reliability, clarity, and discipline are built in from the start, growth becomes easier, not harder.

If you are planning a private label capsule program or reassessing an existing one, the most valuable next step is to pressure-test your assumptions before you scale. Map your end users, document your machine landscape, and challenge suppliers to prove compatibility and consistency with real data, not promises.

If you would like support reviewing capsule options, validating compatibility, or structuring a private label program that can scale reliably, consider starting a technical and strategic conversation early. The right guidance at this stage can prevent costly corrections later and help you move forward with confidence.

We’re here for you – contact us for further information and support.

FAQ

Can I differentiate my brand if many other companies sell “compatible” capsules?

Yes. Most differentiation comes from roast profile tuned for capsule extraction, consistent QC, strong branding and positioning, and dependable supply for B2B accounts.

Should I prioritize price or performance in my first capsule line?

If you are building a long-term brand, prioritize performance. A cheaper capsule that triggers returns and negative reviews can cost more than a higher-quality capsule that runs reliably.

What is the best way to reduce customer complaints?

Over-invest in pilot testing and lot traceability early. Most costly complaints are driven by repeatable manufacturing drift, not random bad luck.

If I sell internationally, what is the simplest way to keep the product consistent?

Standardize the capsule spec and validation methods, then standardize your coffee parameters and sensory targets. Consistency is a process, not a single supplier choice.

What should I do if a B2B customer asks for proof of sustainability?

Provide specific, documentable claims. Avoid vague language. If you discuss recycled aluminum benefits, keep it grounded in credible sources and avoid overpromising.

Do I need a subscription model for B2B capsule customers?

Not always, but recurring ordering options reduce churn and stockouts. Many B2B buyers value predictability more than novelty.

How do I avoid getting stuck with too much inventory?

Start with fewer SKUs, validate demand with smaller pilots, and negotiate staged production where possible. Inventory risk is a common concern in private label setups.

What is a “red flag” when talking to capsule suppliers?

When a supplier cannot give clear specs, tolerances, testing methods, or traceability. If everything is “trust us,” assume you will pay for it later.